Cutting-Edge Lightweight Solutions

Lightweight consulting

We empower your projects with innovative lightweight solutions, tailored to your needs.

lightweight consulting for Tailored Solutions

Our consulting services combine deep technical expertise, advanced simulation tools and cutting-edge manufacturing insights to help you achieve maximum performance, efficiency and sustainability. Whether it’s weight reduction, improved energy efficiency or cost savings – together, we’ll unlock the full potential of your components.

Let’s shape the future of Lightweight Engineering!

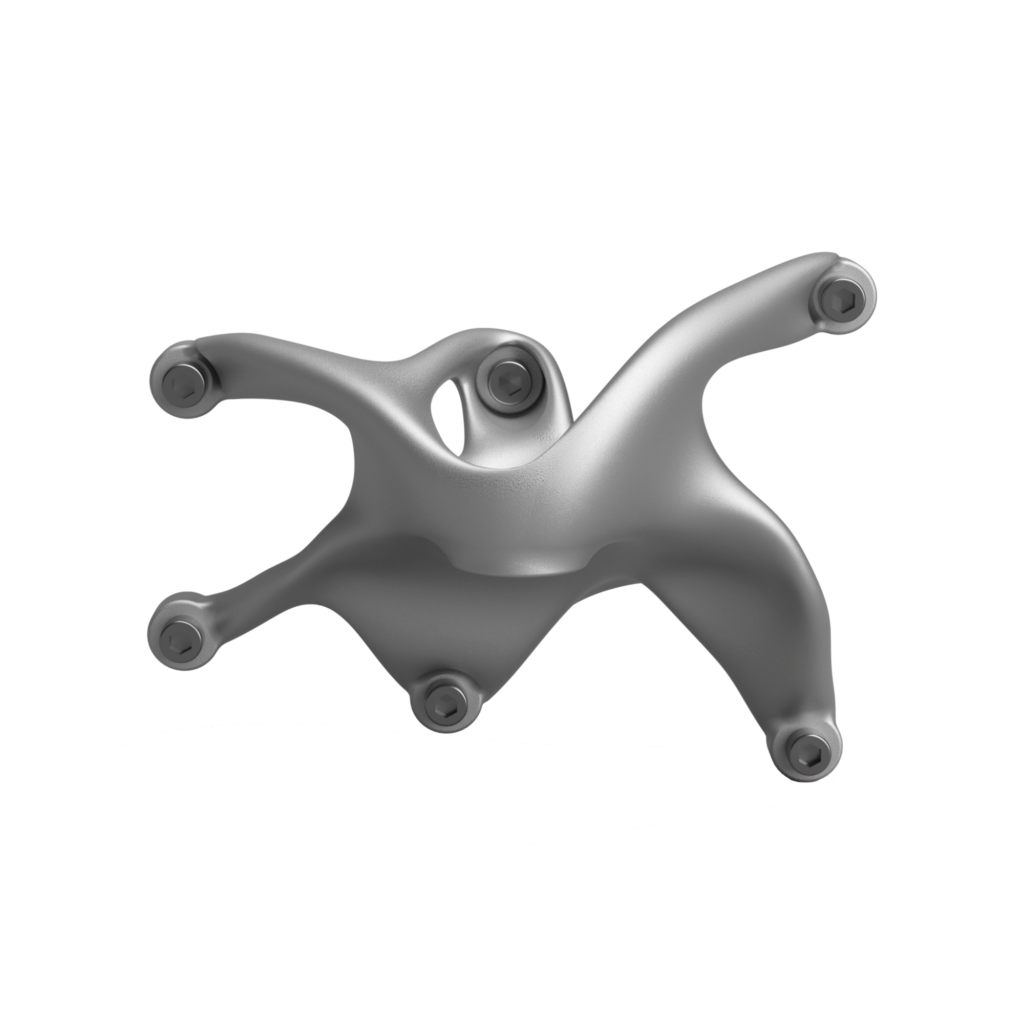

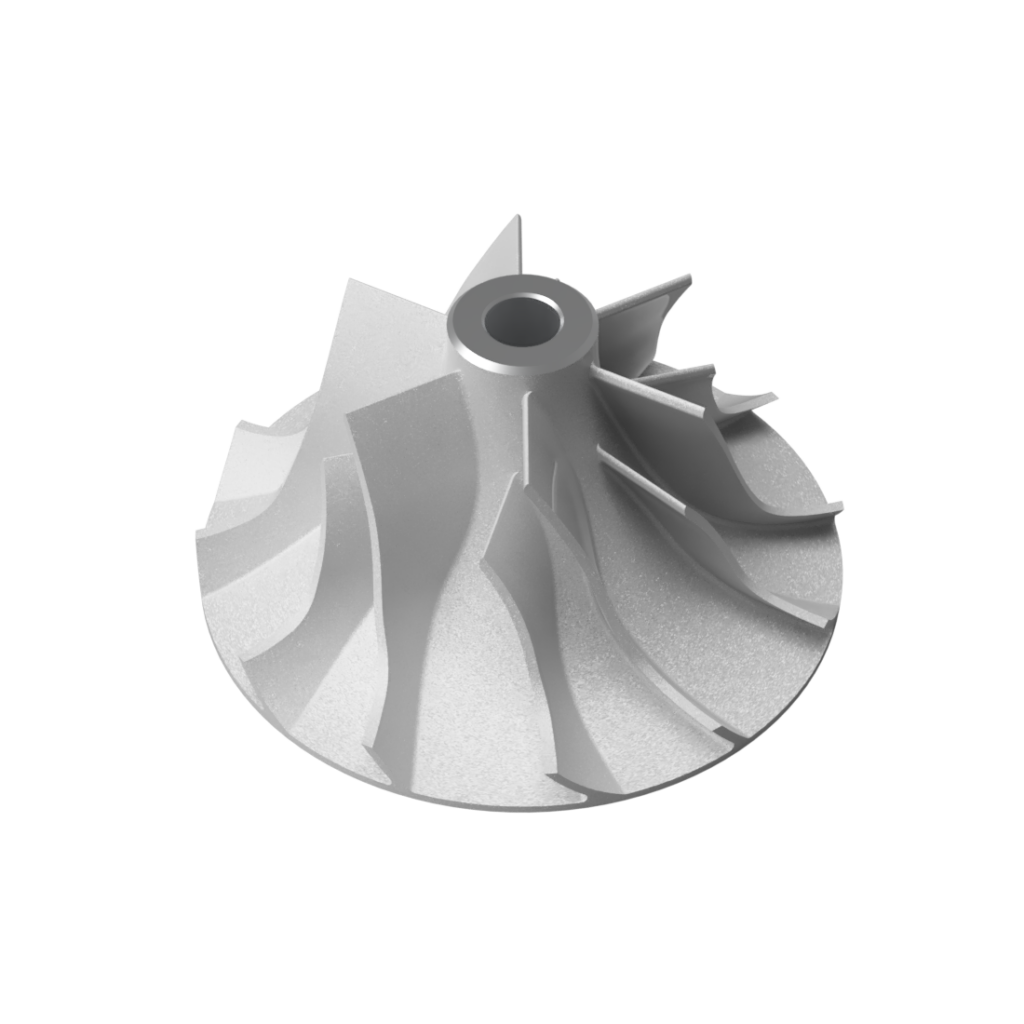

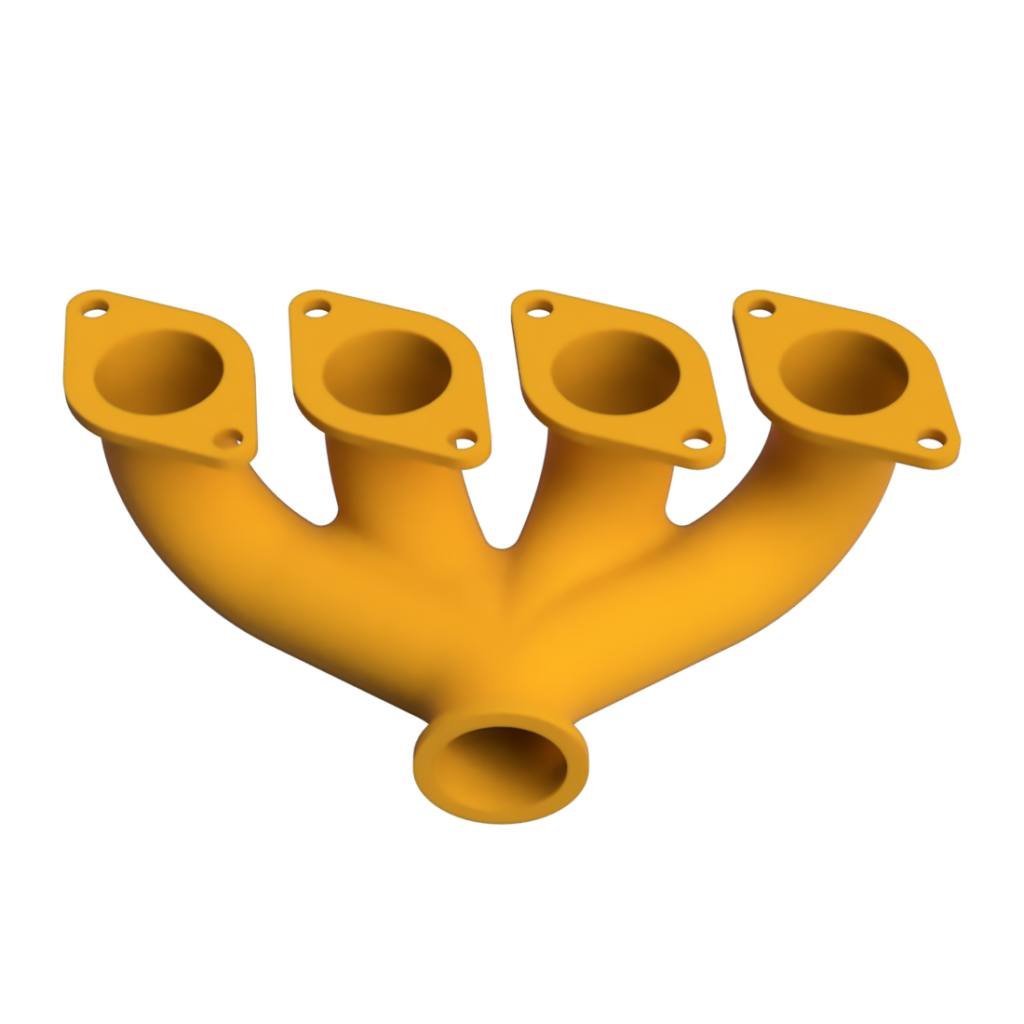

Additive Manufacturing - The advantages at a glance

Fast

Direct production on the basis of CAD data allows us to guarantee very short delivery times from 24 hours. There is no need for tools at all.

High Performance

Additive manufacturing coupled with the innovative power of nature enable the performance of your components to be significantly increased.

Individual

The design freedom of additive manufacturing allows your products to be meticulously tailored to your exact requirements.

Flexible

From the large material­ variety, the suitable material for each application­ case can be determined individually.

Innovative

Additive manufacturing enables the implementation of complex components that would not be feasible conventionally.

Economical

Production-optimized components in small batch sizes help you to exploit significant savings potential.

Sustainable value creation

Industrial 3D printing offers brilliant design freedom. The new possibilities initiate a high increase in efficiency on several levels. Particularly noteworthy in this context is the weight saving with simultaneous performance increase through suitable component design. At the same time, rapid manufacturing is enabled. While conventional manufacturing processes require the use of individual molds and special tools, the geometry is generated directly from the CAD data set in the course of additive processes.

Lightweight consulting: Special features of component identification

Compared to conventional manufacturing processes, the costs in additive manufacturing are almost detached from the component complexity. Manufacturing costs are much more defined by the component volume and in particular by the component height. At the same time, the one-off costs are negligibly low due to the mold- and tool-free production, even for small quantities. As a result, industrial 3D printing can develop its potential especially with increasing component complexity and small batch sizes.

Would you like more information?

Contact us. We will be happy to support you.

Contact details:

Lightbau Engineering GmbH & Co. KG

-

Steinenbergstr. 10

DE-72622 Nuertingen - +49 173 5929938

- info@lightbau.de